HOME

SERVICES

SERVICES OVERVIEW

WE LEAD IN HARD CHROME PLATING SOLUTIONS

INDUSTRIAL HARD CHROME PLATING :

INDUSTRIAL HARD CHROME PLATING :

Hard Chrome Plating has acknowledged the standard of Metal Finishing procedure especially for machine parts like pivoting parts of engines, pumps, compressors, using pressurized water and pneumatically worked gear and so forth which are liable to wear and tear because of contact.

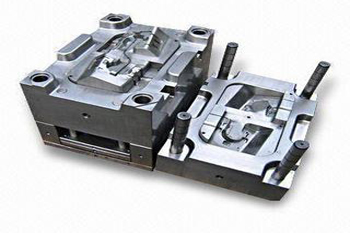

SUPER MIRROR AND DIAMOND POLISHING:

SUPER MIRROR AND DIAMOND POLISHING:

Hard Chrome India suppliers super mirror and precious stone cleaning in molds and printing moves according to clients prerequisites We likewise do jewel and mirror clean. Infusion shaping molds. Elastic parts molds.

CYLINDRICAL GRINDING :

CYLINDRICAL GRINDING :

Our Cylindrical Grinding Services shields machine parts from erosion and wear from intense conditions. Besides, we are giving these machining administrations to our regarded customers at debatable charges.

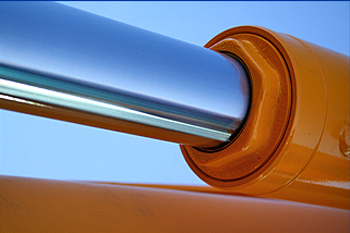

hydraulic-cylinder-repair

hydraulic-cylinder-repair

Inferable from the rich mechanical experience and ability around here, we are associated with giving Hydraulic Cylinder Repairing Service.

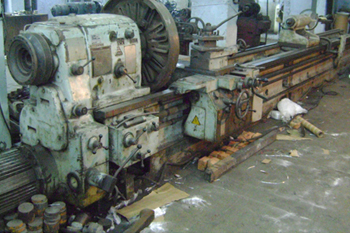

Lathe Machine Work

Lathe Machine Work

Our customers can benefit from us premium quality Lathe Machine Job Work. This administration is rendered according to the necessities of our customers

Hard Chrome Plating Aluminium Textile Roller

Hard Chrome Plating Aluminium Textile Roller

We are note worthy firm in this industry, engaged in providing a wide range of Hard Chrome Plating Aluminium Textile Roller.

Hardchrome Plating

Hard Chrome plating is an electrolytic method of depositing Chrome for engineering applications, from a Chromic acid solution.

High Hardness

High Hardness

Electro-deposited Chrome is extremely hard, with typical values of 850 – 1050 HV (63 – 70 HRc), hence the term “Hard” Chrome. This makes it an excellent coating for wear resistant and abrasion resistant applications such as Moulds and Dies, Punches, Bearing and Seal surfaces, and sliding components.

Low Coefficient of fricton

Low Coefficient of fricton

Hard Chrome has a very low coefficient of friction, approx. one half that of Steel. The coefficient against Steel of 0.16 lubricated (0.21 dry), makes it ideally suited for such applications as Bearing and Seal surfaces, and machinery components.

Wear Resistance

Wear Resistance

The high hardness and low frictional properties of Hard Chrome provide it with extremely good resistance to abrasive and erosive wear, extending the life of components such as Moulds, Dies and Punches etc, up to ten times in most cases.

Corrosion Resistance

Corrosion Resistance

Hard Chrome has an extremely high resistance to atmospheric oxidation, and a good resistance to most oxidising and reducing agents.(with the exception to Chlorides and other Halides), hence its wide-spread use in the Food and Chemical Industries.

Sacrificial Wear Layer

Sacrificial Wear Layer

Since Hard Chrome deposits are readily removed with chemical strippers, without detrimental effect to the base material, the part can be stripped and re-plated repeatedly, when wear shows, without loss or damage to the base part. This is a significant advantage for high wear, high cost parts such as Plastic Moulds and Dies where abrasive filled plastics are used.e

Machining

Machining

Hard Chrome deposits can be successfully finished by grinding, linishing or polishing.

SERVICES LIST

INDUSTRIAL HARD CHROME PLATING

TURNING WORK

SUPER MIRROR AND DIAMOND POLISHING

CYLINDRICAL GRINDING

MOLD FINISHING & POLISHING

Lathe Machine Work

Applications

Hydraulic and Pneumatic Piston Rods and Cylinders

Plastic and Rubber Rolls, Moulds, Dies, Screws, etc.

Press Tools and Punches

Print Cylinders and Plates

Valves, Gates and Bodies

Pump Shafts and Rotors

OUR ADVANTAGES

QUALITY WORK

COMPETITIVE PRICING

SKILLED TECHNICIANS

PICKUP & DELIVERY 24/7

HARD CHROME PLATING

HYDRAULIC-CYLINDER-REPAIR